Steam Return Line Project

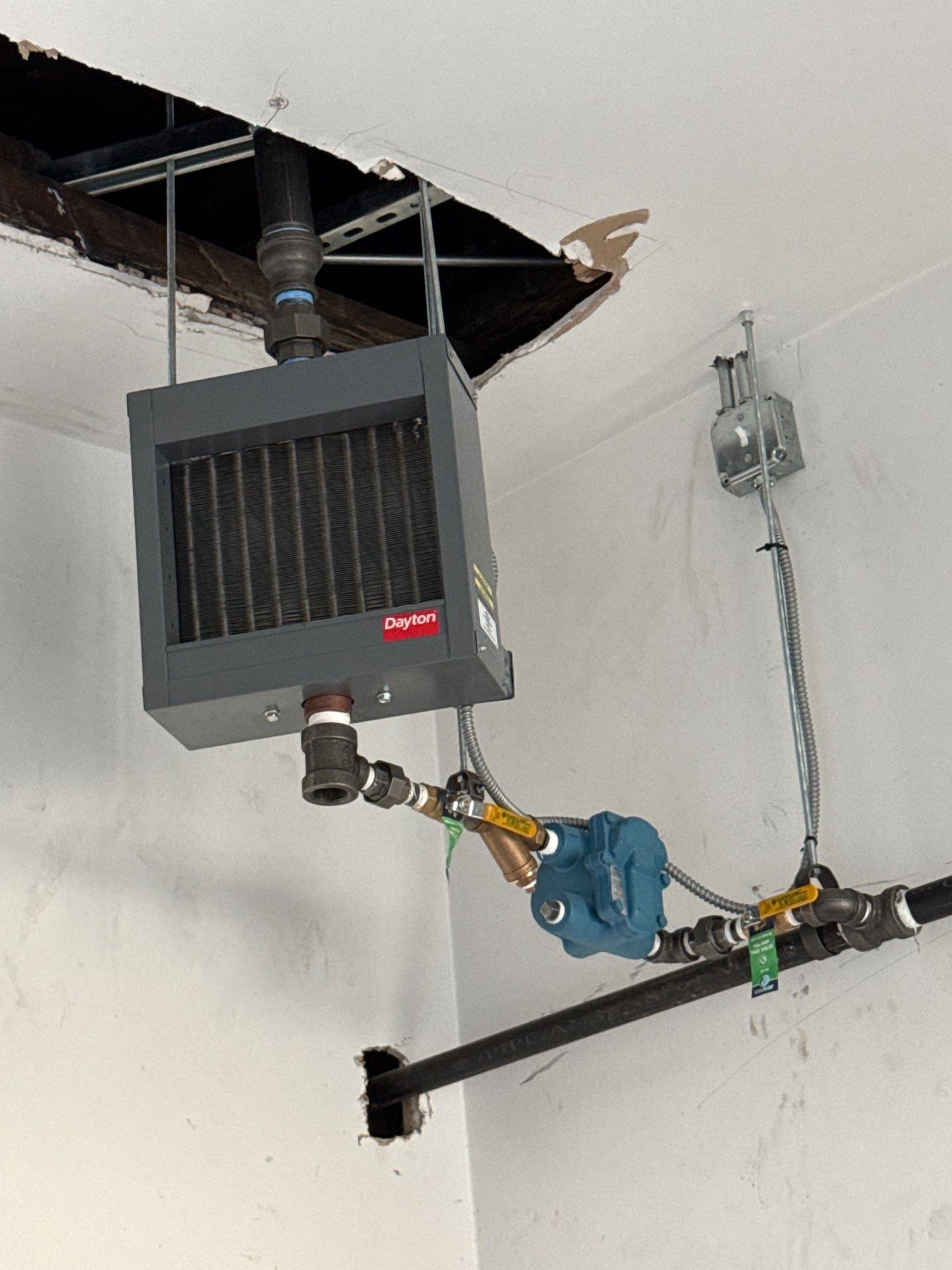

Extensive corrosion and active leaks were found in the underground steam return system spanning over 250ft, resulting in major heat loss and reliability issues. We engineered and installed a complete new above-ground return system, eliminating the failing buried piping. One new condensate unit with properly sized steam traps was installed, and a second existing failed unit was replaced. In the commercial spaces where piping was run overhead, we installed new steam coil blower units to provide consistent and efficient heating. The result is a steam system built for performance, serviceability, and long-term durability.